Equipment

Explore our diverse range of compounding equipment—designed to streamline workflows, automate processes, and deliver reproducible quality, all while adapting to the needs of the future.

Shop equipment

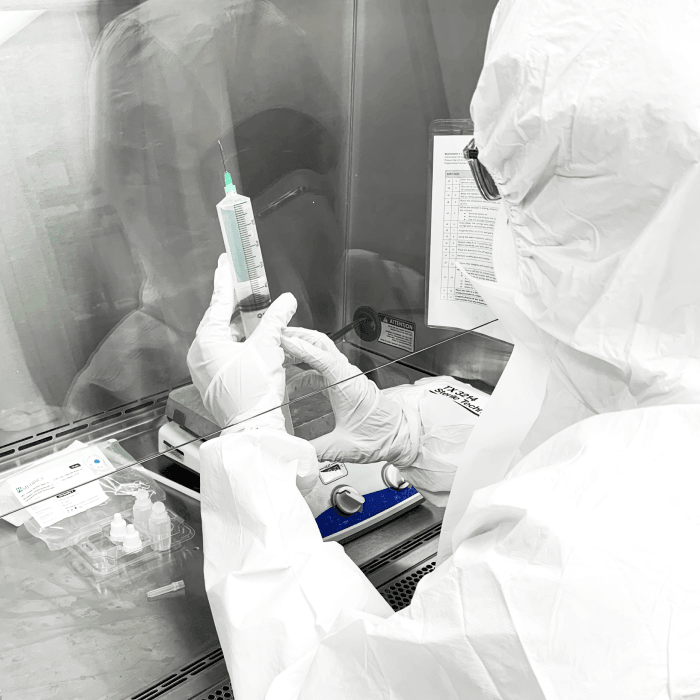

Non-sterileSterile

Find the right

pharmacy hood

Whether you're compounding sterile or non-sterile preparations, our pharmacy hoods provide the containment and control needed to support safe, effective workflows.

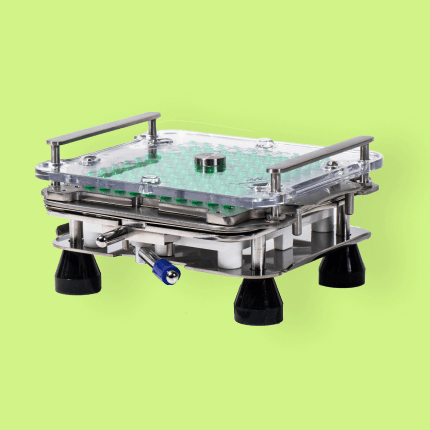

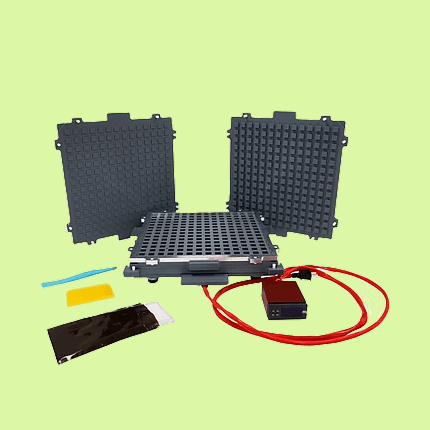

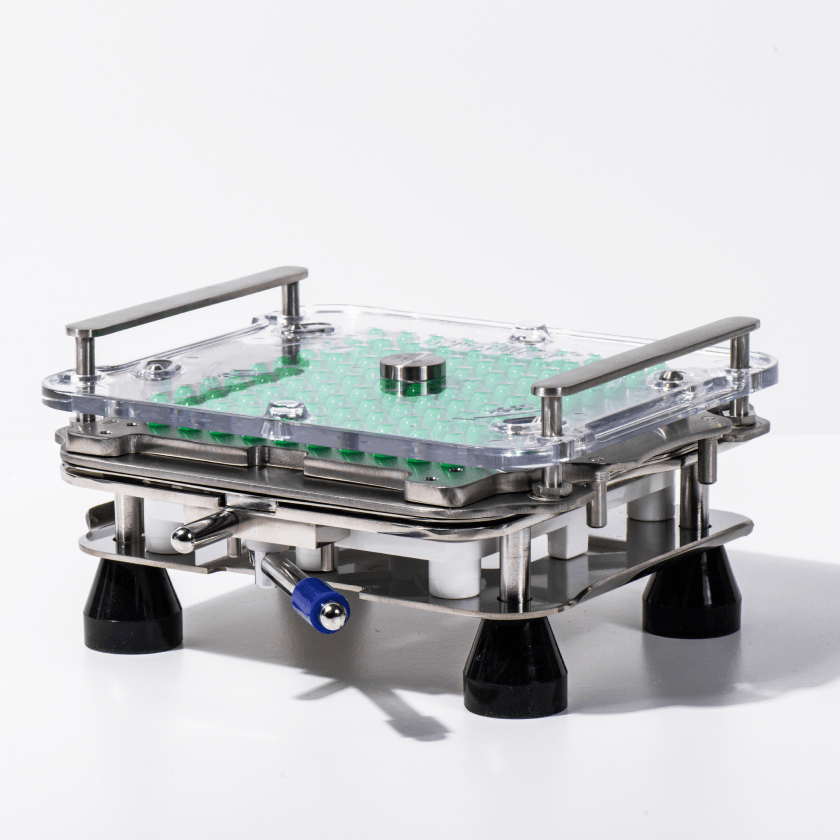

Achieve efficient

capsule filling

Boost productivity with a capsule machine designed to streamline your workflow, reduce preparation time, and deliver repeatable results—batch after batch.

Customer

favorites

The Medisca MAZ® mixer is a versatile mixer and deaerator system perfect for creams, gels, ointments, and liquids. Its vacuum-like function removes air entrapment, combining mixing and deaeration in one step. With no need for mixing rods or blades, it achieves high-speed mixing up to 2000 rpm and reduces processing times.

Learn moreEverything you need

to equip your lab

Discover innovative solutions that streamline your compounding process and boost efficiency at every stage of your workflow.

Adhere to USP standards

Ensure your equipment purchases comply with USP regulatory standards.

Standard operating

procedures

Streamline compliance and achieve accreditation with Medisca standard operating procedures (SOPs). Downloadable, customizable, and user-friendly compounding procedures that support regulatory adherence and elevate standards of practice.

Specialized

consultations

Experience personalized one-on-one support with our expert team of consultants, drawing on more than 20+ years of compounding experience.

Need help

getting started?